CBN GRADE

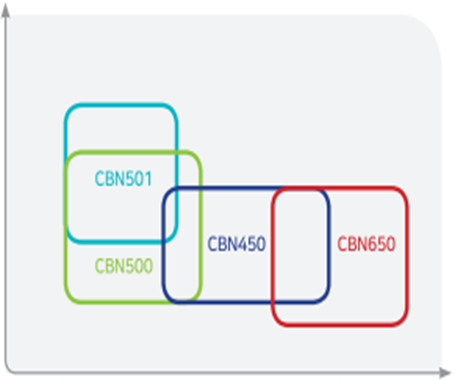

| Classification | Grade | Density (㎛) |

Binding Material |

Feature | ||||||

| Hardened steel+A132:G138 | CBN 4500 | Sub-㎛(1<) | TiCN | * Excellent wear resistance by micro CBN and heat resistant bond * Application: Interrupted and general cutting in high speed & feed for Hardened steel | ||||||

| CBN 5000 | 2 | TiAlloy | * Excellent wear resistance by a hard bond * Application: Finishing, continuous and light interrupted cutting for hardened steel | |||||||

| CBN 5010 | 1~2 | Tic | * Excellent wear resistance due to high heat resistance material * Application: Finishing and continuous cutting for hardened steel | |||||||

| CBN 6500 | 1~4 | TiCN | * Various cutting application available made by the material containing wear resistance and heat resistance *Application: continuous and medium interrupted cutting for hardened steel | |||||||

| CBN 730S | 10 | Ceramic | * High crashworthy and heat resistance * Application: Suitable for cutting hardened Cr Alloyed steel | |||||||

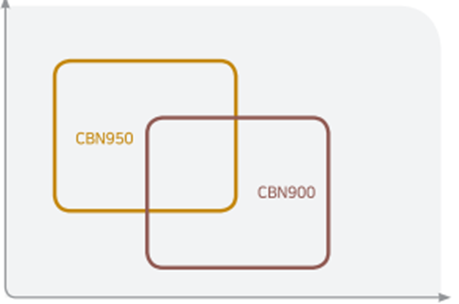

| Alloyed steel / Cast iron |

CBN 9000 | 2 | Ceramic | * Excellent wear resistance and breakage resistance due to high Content of CBN and highly sintered structure * Application: Widely used for lapping or high speed cutting for alloyed steel and cast iron | ||||||

| CBN 9500 | 3 | TiAlloy | *Excellent fracture resistance and reinforced holding power by optimal binding *Application: Finishing for cast iron | |||||||

| Cutting speed >> |  |

|

||||||||

| Light , medium, and heavy interruption | ||||||||||

|

||||||||||

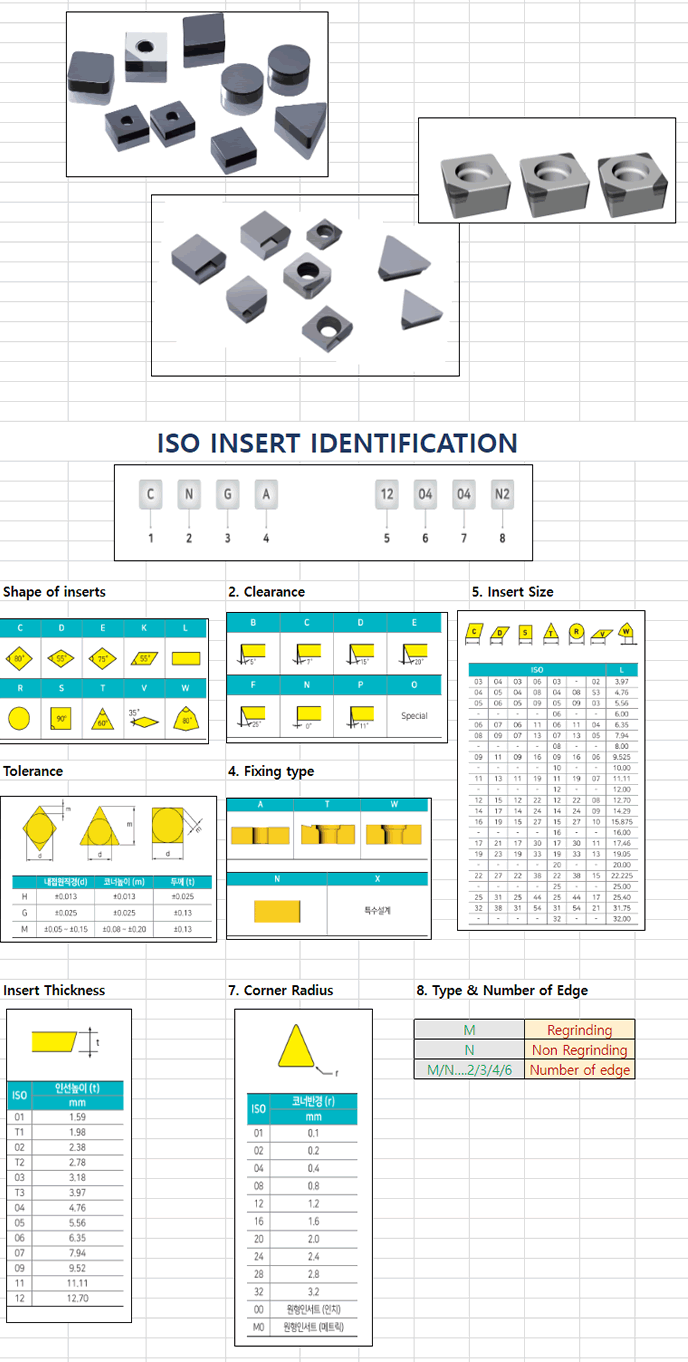

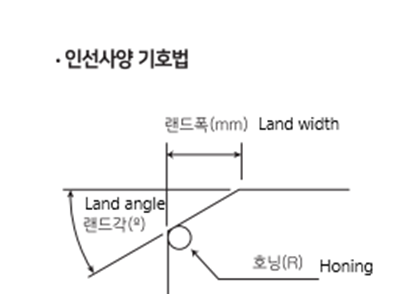

| CBN cutting-edge notation | ||||||||||

|

*Stndard cutting edge

|

||||||||||

| Division | Land width(mm) | Land angle(º) | Honing® | |||||||

| Steel | 0.1~0.2 | 25º | 0.01~0.02 | |||||||

| Cast iron | 0.1~0.5 | 20º | <0.01 | |||||||

| Interruption | 0.2 | 30º | 0.01~0.03 | |||||||

| CNGA 120408 0150250020 | ||||||||||

| 015 025 0020 | ||||||||||

| Land width Land angle Honing | ||||||||||