|

||||

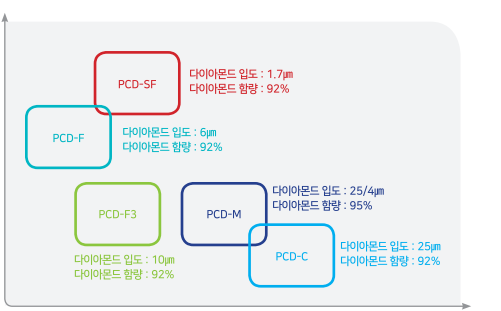

PCD GRADE |

||||

| Grade | Density (㎛) |

Feature | Application | |

| PCD-SF | 1.7 | High-density sintering of ultra-fine diamonds provides both wear resistance and breakage resistance. | For the process which requires high surface finishing such as Alloyed aluminum, Alloyed copper, Wood composite and Plastic. | |

| PDC-F | 6 | As manufactured by sintering fine diamond grains, each grain is strongly bound to each other, the balance between workability and abrasion resistance is excellent. | ||

| PCD-F3 | 10 | Excellent wear resistance & impact resistance |

Alloyed aluminum (below 14% of Si), alloyed copper, graphite, graphite composite, synthesized wood, half sintered ceramic tungsten carbide | |

| PCD-M | 25/4 | Fine diamond and large-grain diamond are combined in two phases to provide excellent impact strength and abrasion resistance. | Metal composite, High silicon alloyed aluminum (over 14% of Si), glass fiber, glass fiber reinforced board and reinforced wood. | |

| PCD | 25 | By sintering of large grain diamond, it contains the highest content of diamond and high wear resistance |

High silicon alloyed aluminum (over 14% of Si), metal composite, sintered ceramic, double metal compound(aluminum, ductile iron) and other abrasion resistance material. | |

| Impact Resistance |

|

Wear Resistance | ||

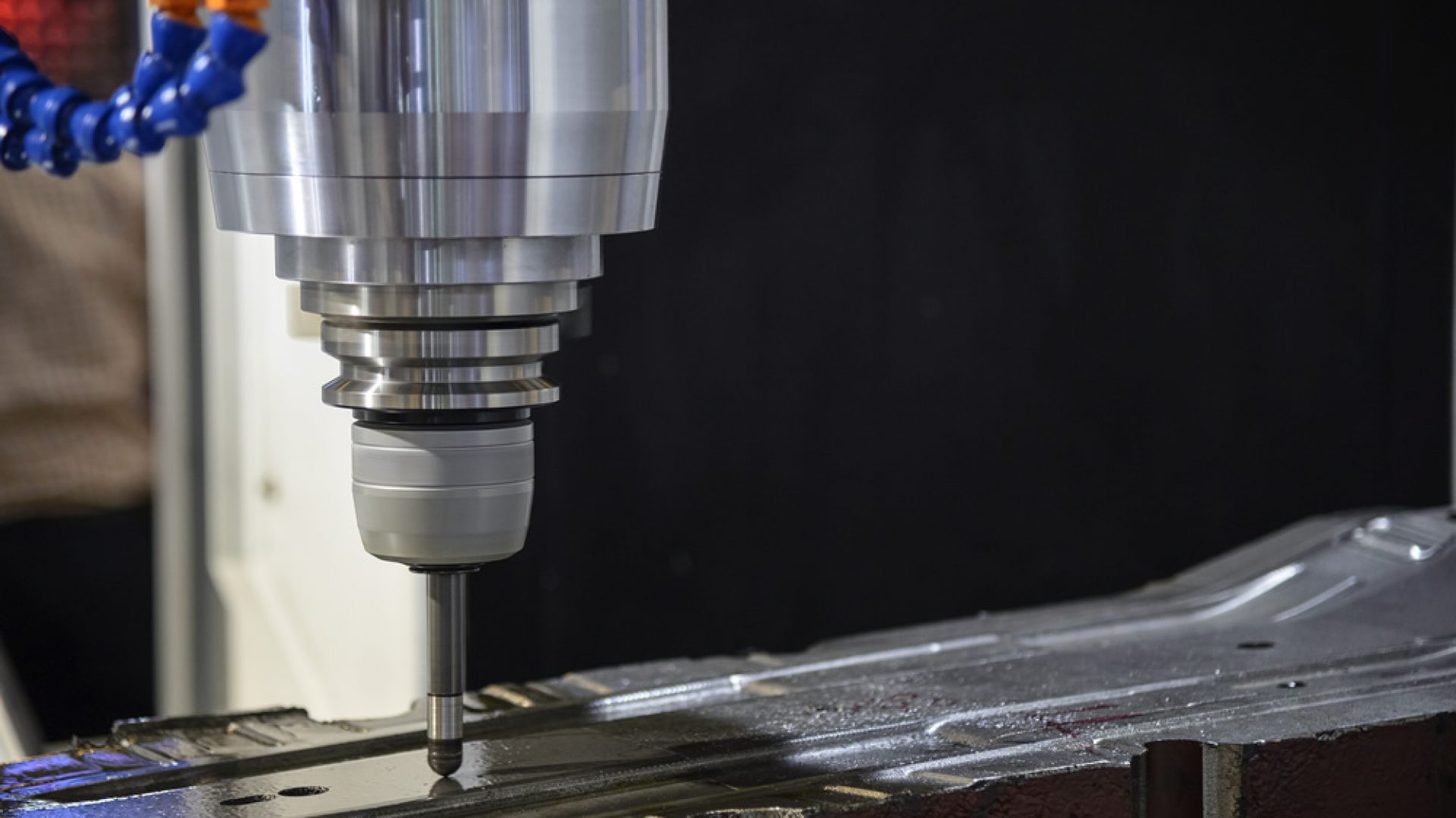

A.M TECH

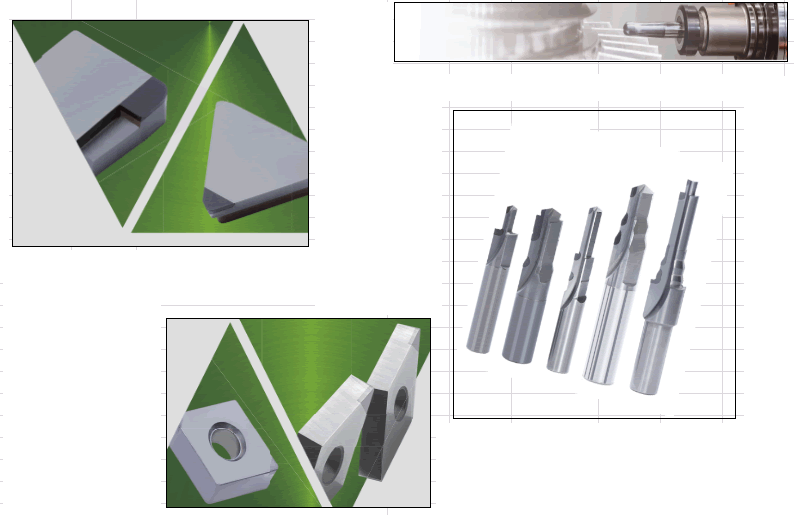

Carbide cutting tool -Endmill , Drill …